— 11 min read

How to Improve Construction Safety

Last Updated Dec 8, 2023

Putting aside all the intricate budgets, extensive timelines and processes, safety will always come first. After all, construction safety can affect all aspects of a project just as seriously as hindrances that prevent its completion.

These safety measures maintain a secure work environment in a construction area. These measures must be taken by each individual for safety to be successful. Therefore, safety management should be an integral part of each construction management company.

Construction safety in construction management is designed to help avoid injury or death, severe work delays, high insurance costs, and hefty fines for the company.

In Australia, construction management companies are taking a serious look at their construction safety and how it can be improved to meet the needs of the adapting workplace.

Whether you’re just starting out in construction safety how-to, or you’re a safety expert who wants to keep learning and hardening skills, this article will take you on an exploration of everything you need to keep your team safe in any circumstance.

Contents

Table of contents

Frequent Causes of Workplace Injuries

Your workers are no strangers to danger. Construction sites are dangerous places to work. There are always hazards that arise and continually change throughout the construction process.

The Australian construction industry is the third most deadly with twice the average fatality rate and is ranked fifth for causing severe injury, according to Safe Work Australia.

Sprains and strains, falls, slips and trips, and even mental health issues and fatal accidents— these are all, unfortunately, some of the most frequent hazards in the construction workforce.

A workplace injury can happen to anyone, and bring a lot of complications for your project. Workplace injury and illness can cause a loss of productivity, reduction of sales, low staff morale, loss of reputation – and at worst – closure of the construction company.

Taking safety seriously means you can responsibly keep your team safe by teaching them proper safety.

When safety is not the first priority, workplace injuries can lead to extensive recovery time, leaving your team members to (try and) rely on workers’ compensation.

Workers’ Compensation

If a team member is injured at work, the standard procedure is to follow your normal workplace injury procedure and, of course, seek medical attention if required. This should be set up in your construction safety plan.

Those who are injured at no fault of their own may be entitled to workers' compensation. This will cover the cost of any approved medical treatment, rehab, and loss of wages.

However, the workers’ compensation process can be confusing or overwhelming, especially if you are dealing with a severe injury or illness.

Teaching your team about workers’ compensation is the best way to prevent them from having to use it due to injury or disease. Because when it comes to it, workers' compensation is better if you have it but never need it.

Construction Safety Statistics in Australia

The 2023 Australian construction industry can be modelled through different statistics and studies that show exactly how it’s composed and where it is going as the industry grows.

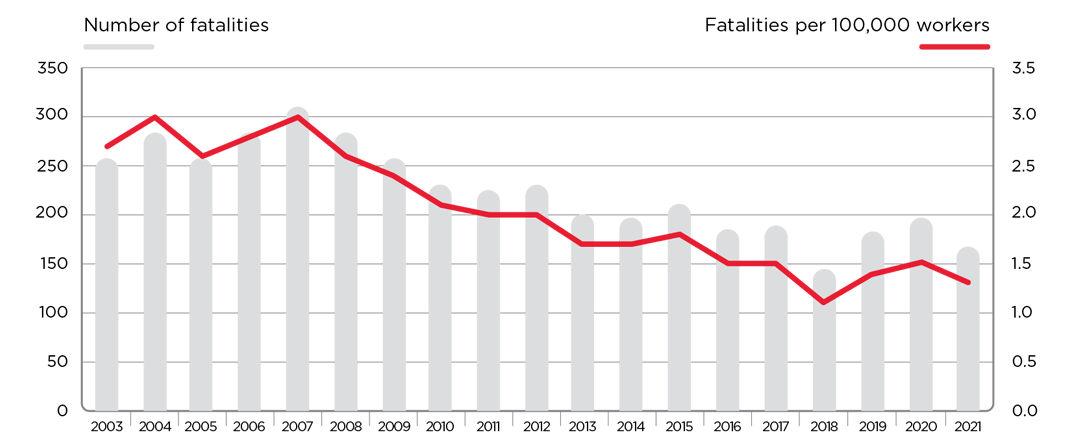

There has been a decrease in workplace fatality in the past 10 years of construction in Australia, and we want to keep that trend moving down.

According to this report by Safe Work Australia, of the 100+ fatalities across Australia each year, the most happen in New South Wales (27%), Victoria (25%) and Queensland (20%).

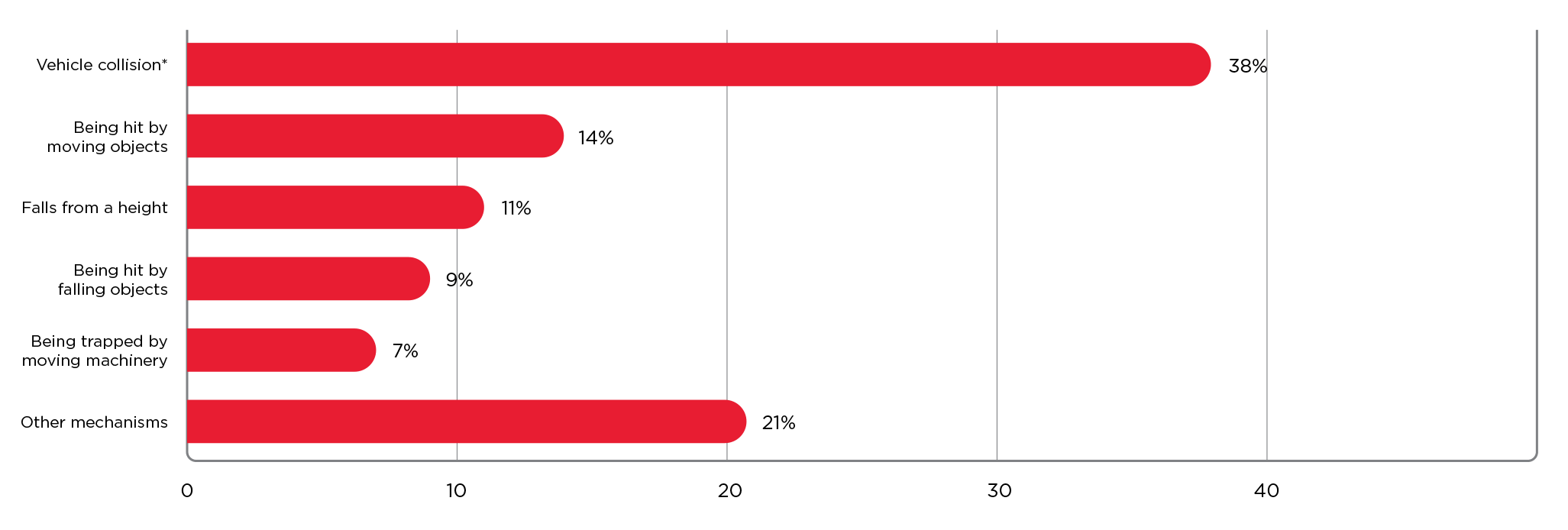

Of all tragic fatalities, many of them are caused by preventable measures. This table shows which kinds of accidents were most often fatal in Australia.

According to a study by ACA Research (on behalf of Procore), less than 50% of companies in Australia train new hires in safety management, and only 37% of workers in high-risk jobs receive adequate training from their employer.

Centralising construction safety and creating a space where meaningful conversation and positive behavioural change can happen will drive positive progress in creating a safer construction industry in Australia.

Steps to Improve Construction Safety

Improving safe construction sites, jobs and safety in construction can have a multitude of positive impacts on the entire industry.

Certainly, the most important benefit of improving safety in construction is helping avoid injury, illness or death. The driver of improvement in construction safety will always be keeping the team safe and putting safety at the forefront of any job at any company.

There are other benefits too, such as reducing (severe) work delays, lowering insurance costs, and avoiding hefty fines for the company, not to mention stronger internal trust, better client relationships and, even, improved sales.

The safest construction companies aim to create practices around shared safety documentation and control. They use software tailored specifically to construction safety management.

Here’s what you can do to help improve construction safety in Australia and how you can responsibly keep your team safe:

1. Improve communication and transparency.

Within any workplace or job site, communication and cooperation are necessary for the success and direction of the job or company. It helps build trust and relationships on a job site, as well as enhance the key aspects of safe company culture.

Being transparent and precise in documentation contributes to good communication among workers as part of any team. Without documentation, missing or unknown information/data can create hazards on a job site. Plus, more information gives your team a stronger understanding of workflow and unseen pieces go overturned. With strong communication, teams are always prepared – throughout the day and throughout the project.

Strong documentation practices help reduce these risks. Improving communication and transparency are vital components of construction project safety.

2. Create a Quality Management Plan (QMP).

A very important piece of documentation in your construction organisation is the Quality Management Plan (QMP). It is also commonly known as the construction safety management plan.

In Australia, it is straightforward to understand what safety management plans and processes you must have in place for construction projects of any size. To refresh your memory, you can access the legislation here.

The QMP properly documents the necessary information to effectively manage project quality from start to finish.

Within the QMP, there is also information about the project's quality policies, procedures, criteria for–and areas of–application, as well as roles, responsibilities and authorities.

Who completes the QMP?

A thorough construction Quality Management Plan (QMP) is a worksite document that covers every quality aspect required for a specific job or project, including safety. Many sites do not have an adequate Work Health & Safety (WHS) plan in place and face significant issues when problems or incidents arise.

The bottom line is that safety management is the responsibility of everyone on the site.

But who’s responsible for writing it down?

The QMP must be prepared by the head contractor before the project commences. It is important that the safety plan is understood by every worker on the site and made available at all times to any person engaged to carry out the construction work. It must be updated, and people must be notified when revisions are made to the original.

3. Implement an ITP for your construction project.

Creating and implementing an Action Plan to digitise Inspection and Test Plans (ITP) for your construction project can boost construction safety.

In the construction industry, the ITP is all about quality assurance. Quality assurance is the top priority for any construction worker – be able to provide the highest quality of service to customers.

An ITP is an important piece of documentation that must be present and accessible to ensure your construction project is moving on track and also following regulations and guidelines.

Data and insight can help move projects forward with confidence. Inspections reporting gives you the ability to track the frequency, outcomes, and detailed performance of an individual inspection (or group of inspections).

Pass pre-wall sheeting and formwork concrete inspections effortlessly with ITP templates that can be turned into Action Plans in just a few clicks. Construction companies who use online software to create and implement their ITP find greater success due to a number of features and automation.

Inspection Software solutions and features let your business:

- Create, manage and build your own company-wide inspection library for ongoing reflection and success by continuously adding to them and creating project-specific templates for unique project needs.

- Report a deficient item or safety violation immediately by creating an in-app observation.

- Manage and review reports of your inspections on the go. Identify quality and safety trends across your project or portfolio, all from your desktop or mobile device.

- Link an inspection to a drawing and attach photos and/or supporting documentation.

- Assign a responsible party and due date to your observations, and manage your deficiencies through completion.

Here are ITP templates for concrete and pre-wall sheeting available for you to download instantly.

4. Include safety as part of your culture.

Create safety and maintain it by understanding, predicting, and correcting issues before they become a real threat. Your culture should go beyond referencing previously documented issues or mindlessly accessing construction safety documentation. The ideal construction site culture should be prone to identifying safety issues, so you can provide the highest quality build in the safest environment every time.

By making safety a part of your culture, you are able to create and maintain a conversation around safety in the workplace. You are able to create a subconscious awareness of safety in your worksites and in your team members and their duties.

Ensure each member understands their WHS duties.

Work health and safety (WHS) laws enlist the aid of many different people with various duties. Every team member should completely understand and be capable of complying with them.

Within the WHS, the risks associated with the project and the various procedures are in place to ensure that the site is kept as safe as possible. Included in the WHS are safety inspections, contractor SWMS approvals, evacuation procedures and project risk matrices.

Under the WHS Act, each member involved has WHS duties. In construction work, the person conducting a business or undertaking (PCBU) is the primary duty holder for WHS and must manage risks to keep people safe.

As a PCBU, ensuring the health and safety of workers and others at your workplace is your top priority.

But there is also a responsibility that must be taken by the rest of your team to ensure adequate safety.

Incentivise safety training.

To boost construction safety and have your team take it seriously, you must follow the lead of construction organisations that have started to incentivize safety training.

According to NSW Safety Regulators, as part of this new emphasis, safety incentive strategies reward employees who take positive steps to improve WHS on all sites. They can focus on achieving behaviour changes that reinforce positive behaviour to create a good WHS culture.

Utilise proper signage.

It may seem apparent, but many construction companies do not use proper safety signage.

A sign's main purpose is to tell workers what hazards are present and how they avoid those dangers.

To be most effective, these signs must be clear and properly located so that workers will know what to do to stay safe in different work environments.

5. Provide your team with the proper equipment.

Workplace injuries are avoidable tragedies, so you should be aiming for zero workplace injuries. With the right tools, your team will be equipped, and the construction site will be safe.

With an online platform full of important information, tools, resources and communication, you can ensure that your team is connected to the safety information they need and can foster a safety-first workplace culture.

Improving Your Construction Safety Approach

Construction site quality and safety software can empower construction companies to go beyond checking the boxes of safety.

Here are just some of the advantages that software provides to companies of any size -- enabling them to put safety first:

- Identify hazards before injuries occur.

- Create a site diary to track of every detail such as communication, equipment, materials, labour and jobsite events.

- Utilise safety forms to exceed the expectations of third-party stakeholders and additional project collaborators.

- Track observations to assign follow-up responsibilities and report multiple types of jobsite activities.

- Capture incidents to create a portfolio of injury and near-miss records that your team can use to identify risks and take preventative actions.

- Centralise your data to create a command centre at your fingertips.

- Digitise safety documents to simplify review, access markup tools and easy file intake to support naming convention requirements.

- Predict trends with reporting on insights into your business and field operations.

- Create action plans to execute, collaborate and achieve high-quality outcomes with ease.

Excellence in Efficiency

The safest construction companies aim to create practices around shared safety documentation and control, typically by using software and programs that enable the whole team to access up-to-date information when they need it.

Categories:

Tags:

Written by

Emma De Francesco

16 articles

Emma is currently Strategic Product Consultant at Procore where she loves partnering with clients to help them achieve the best possible results. She has worked as a Project Manager in previous roles, responsible for overseeing small to medium-sized projects across various sectors including commercial, health and lifestyle, retail, government and hotels. Throughout these projects, she managed everything from project costs, program and quality & safety, to design management, procurement, and authority approvals.

View profileExplore more helpful resources

Construction Defect Lists Explained

A defect list is a document that lists the final tasks remaining before a construction project — or scope of work — is considered complete. Builders add all work that...

Construction Estimating: The Building Blocks to Success

Construction estimating is a crucial process in the construction industry, as it involves accurately predicting the cost of a project before work begins. Within Australia and New Zealand, construction estimating...

RFQs Explained: How Contractors Prove Their Qualifications

In the construction industry, the term RFQ can mean two very different things: a request for qualifications, or a request for quote. When an owner-developer uses a request for qualifications...

RFIs: A Contractor’s Guide to Requests for Information

Head contractors spend a lot of time waiting for owner-developers to respond to their requests for information (RFI). So much so, that if they were to add up all the...